Significance Statement

The use of polypropylene foams in spite of their benefits in industrial production faces certain demanding situations because to their high level of cell coalescence and cell collapse during the foaming process. Numerous technologies developed in order to provide a better polypropylene foaming behavior also faces certain limitations. However, it has been discovered that the long-chain branching of polypropylene offers an easy and viable approach in improving its foaming features. The efficient use of foam injection molding technique for the fabrication of long-chain branching polypropylene foams have not been utilized to develop foams with high expansion ratios.

Kyoto University researchers led by Professor Masahiro Ohshima investigated a new long-chain branching polypropylene to fabricate 10-fold expansion ratio foams with the use of a core-back foam injection molding. The research is published in the journal, Industrial & Engineering Chemistry Research.

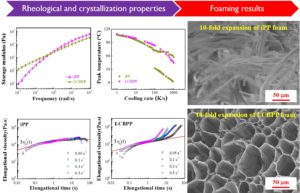

When the authors looked at the oscillatory shear flow properties, higher storage modulus for the long-chain branching polypropylene was found at lower frequency compared with isotactic polypropylene but had a reduced storage modulus was observed for the long chain-branching polypropylene at higher frequency which indicates a slower relaxation process of the long-chain branching in favor of the foaming process. Additionally, the results observed under uniaxial elongation flow behaviors indicated a notable strain hardening property at various Hencky strain rates for the long-chain branching polypropylene, which would also favor the foaming process.

The long-chain branching polypropylene polymers exhibited a high peak crystallization temperature at a very high cooling rate compared with the isotactic polypropylene which had double crystallization peaks at a lower cooling rate. The attributes found in the long-chain branching polypropylene polymers indicated a high heterogeneity which favors crystal nucleation.

The expansion ratios of the long-chain branching polypropylene polymer foams as characterized by scanning electron microscopy confirmed the fabrication of 10-fold expansion ratio with a 90% weight reduction, which is the lowest achieved so far. The cell density and cell size of the long-chain branching polypropylene foams was respectively higher and smaller than the isotactic polypropylene.

The long-chain branching polypropylene at all foaming temperatures had lower cell sizes compared to the isotactic polypropylene, indicating presence of uniform cell structure with high expansion ratios. The long-chain branching polypropylene also had a small open cell content at all foaming temperature as a result of the presence of high strain hardening property. The foam processing windows became larger for the 10-fold long-chain branching polypropylene.

The attributes achieved in the long-chain branching polypropylene with a high expansion ratio of 10-folds definitely provides improved applicability for industrial purposes.

Journal Reference

Long Wang, Shota Ishihara, Megumi Ando, Atsushi Minato, Yuta Hikima, and Masahiro Ohshima*. Fabrication of High Expansion Microcellular Injection-Molded Polypropylene Foams by Adding Long-Chain Branches, Industrial & Engineering Chemistry Research 55 (2016) 11970-11982.

Department of Chemical Engineering, Kyoto University, Katsura, Kyoto 615-8510, Japan.

Advances in Engineering Advances in Engineering features breaking research judged by Advances in Engineering advisory team to be of key importance in the Engineering field. Papers are selected from over 10,000 published each week from most peer reviewed journals.

Advances in Engineering Advances in Engineering features breaking research judged by Advances in Engineering advisory team to be of key importance in the Engineering field. Papers are selected from over 10,000 published each week from most peer reviewed journals.