Significance

Particle deposition is the spontaneous attachment of particles to surfaces. Particle deposition yields thin films that are considered as the backbone for advanced applications in the various fields, such as: optical devices, environmental applications, telecommunications devices, energy storage devices – among others. To date, various techniques have been reported and considerably advanced in view of depositing flawless coatings. Particularly, the plasma jet in the vacuum plasma spray (VPS) process presents characteristics such as supersonic flow, expanded jet dimensions, and a smaller decay rate for jet velocity and temperature that are distinctly different from those of atmospheric plasma spray (APS). Similarly, solution precursor atmospheric plasma spray (SPAPS) is a process that uses liquid solution precursors of the desired coating material as feedstock injected into a DC arc plasma operated at atmospheric pressure. Although several reports been published on solution precursor and suspension plasma spray using RF plasma under low pressure, however, research on low-pressure solution precursor or suspension plasma spray using DC arc plasma torches is very limited, and most of the work concerns the very low-pressure plasma spray (VLPPS) processes. At present, the growth in demand for superhydrophobic surfaces is persistently pushing for advancement of their fabrication techniques for purposes of yielding durable surfaces.

On this account, researchers from the Centre for Advanced Coating Technologies at the University of Toronto in Canada: Dr. Pengyun Xu (currently a postdoctoral fellow), Professor Thomas W. Coyle, Dr. Larry Pershin and Professor Javad Mostaghimi developed a solution precursor vacuum plasma spray (SPVPS) process to fabricate superhydrophobic Yb2O3 coatings by using Yb(NO3)3 solution as feedstock. Their objective was to combine vacuum plasma spray with solution precursor as the feedstock, thereby delivering an alternative superhydrophobic surface deposition technique. Their work is currently published in the Journal of Thermal Spray Technology.

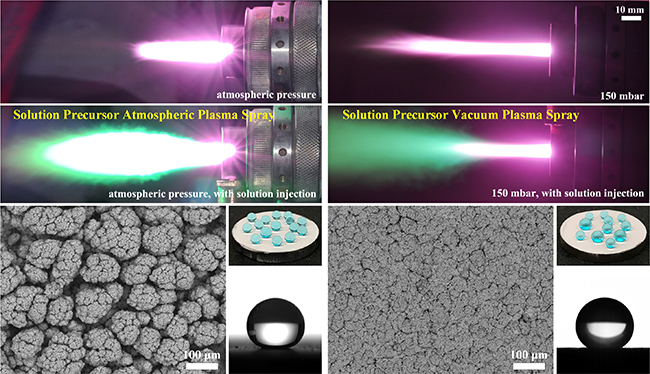

In their approach, SPVPS coatings with different microstructures and wetting behaviors were fabricated by tailoring the process parameters of the spraying process. Further, superhydrophobic coatings were also deposited by SPAPS using the same feedstock. During the experimental setup, plasma jet characteristics, interactions of solution droplets and plasma, microstructure, and wetting behaviors of coatings formed by the two processes were compared and evaluated.

The research team reported that the SPVPS coatings deposited under 150 mbar were denser than the SPVPS coatings deposited under 250 mbar or the SPAPS coatings. The team also noted that SPAPS coatings exhibited obvious columnar structures, which were reduced in coatings deposited under 250 mbar, and further reduced in coatings deposited under 150 mbar. The columnar structures in forms of densely packed slender clusters or large clusters with wide gaps for the SPAPS coatings changed to spherical bumps for coatings deposited under 250 mbar, and became very flat topographies when deposited under 150 mbar.

In summary, the study developed a new solution precursor vacuum plasma spray (SPVPS) process by combining vacuum plasma spray with solution precursor plasma spray processes. To demonstrate its worth and utility, the team used the SPVPS process to fabricate superhydrophobic Yb2O3 coatings by injecting Yb(NO3)3 solution into the low-pressure plasma jet. Remarkably, the obtained results by Pengyun Xu and his colleagues enabled them to explain the formation of different coating microstructures formed via the different plasma jet characteristics, interactions of solution droplets and plasma, and droplets motions upon the impact on surface. Overall, the different wetting behaviors of coatings were correlated with the coating surface structures and topographies.

Reference

Fabrication of Superhydrophobic Ceramic Coatings via Solution Precursor Plasma Spray Under Atmospheric and Low-Pressure Conditions. Journal of Thermal Spray Technology (2019), volume 28:page 242–254.

Advances in Engineering Advances in Engineering features breaking research judged by Advances in Engineering advisory team to be of key importance in the Engineering field. Papers are selected from over 10,000 published each week from most peer reviewed journals.

Advances in Engineering Advances in Engineering features breaking research judged by Advances in Engineering advisory team to be of key importance in the Engineering field. Papers are selected from over 10,000 published each week from most peer reviewed journals.