Significance

Although lithium-ion batteries are widely used in portable electronics and electrified transportation, their future development is uncertain due to their acute safety issues, low energy density and limited lithium resources. This has necessitated developing alternative and more effective rechargeable energy storage systems. Among them, alkali metal-chalcogen batteries, especially potassium-selenium (K-Se) batteries, have attracted significant research attention. This can be attributed to their low-cost, high energy density and collective merit, including desirable electronic conductivity. Nonetheless, the development of K-Se battery technology is hindered by several challenges, including enormous volumetric changes, insufficient utilization of active Se and sluggish reaction kinetics of Se cathode, which would inevitably induce potential rapid capacity decay.

To overcome these challenges, extensive research efforts have been devoted to achieve effective regulation and accommodation of Se species using carbonaceous materials. Carbon architectures have proved effective in enhancing the utilization of Se and minimizing undesirable volume changes. However, an unsatisfactory electrochemical performance due to the poor K-ion diffusion, sluggish reaction kinetics and weak polyselenide adsorption of the carbonaceous substrate. These challenges could be exacerbated by the excess carbon usage that could trigger self-discharging problems and reduce energy density.

Another challenge in developing K-Se system for commercial applications is associated with the difficulty of designing Se cathode with durable and high-loading architecture. Recently, the emergence of 3D printing technology has been extended to fabricating electrodes for energy storage applications with appealing results such as improved cycling lifetime and areal capacity. Nevertheless, there are no reports on the construction of 3D printed Se cathode for K-Se systems despite its potential to overcome most of the above challenges.

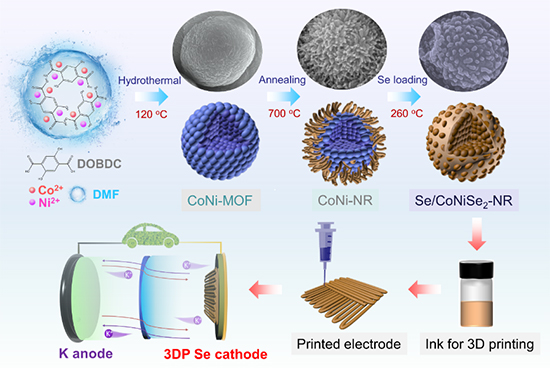

Inspired by the previous considerations, a team of researchers from Soochow University: PhD candidate Yifan Ding, Dr. Jingsheng Cai, Dr. Yingjie Sun, PhD candidate Zixiong Shi, Dr. Yuyang Yi, Dr. Bingzhi Liu and Professor Jingyu Sun developed a Se and CoNiSe2 co-embedded nanoreactor (Se/CoNiSe2-NR) as an advanced cathode for improving the holistic performance of K-Se batteries. The nanoreactor had low carbon content and was fabricated via a combination of Se loading and one-step host construction. A series of electrokinetic analyses and theoretical simulations were carried out to validate the feasibility of the cathode for K-Se battery technology. The work is currently published in the journal, ACS Nano.

The research team revealed the stronger K2Se2/K2Se adsorption and improved diffusion of the K ions owing to the effects of incorporating Co. The advantages of the cathode included a substantial reduction in the irreversible loss of active Se; and effective control of the volume change during cycling was reported owing to the spatial confinement of the Se species within the conductive nanoreactor. Additionally, the direct solid-to-solid conversion improved the cycle stability of the K-Se batteries by mitigating Se loss within the electrocatalytic nanoreactors. As a result, the Se/CoNiSe2-NR cathode exhibited high cycling stability with a low capacity decay rate of about 0.038% per cycle over 950 cycles at 1.0 C. Importantly, the K-Se batteries equipped with 3D printed Se/CoNiSe2-NR electrode with tunable Se loadings enabled steady cycling at elevated Se loading of 3.8 mg cm-2.

In summary, Soochow University scientists reported the successful design of a multifunctional Se/CoNiSe2-NR cathode for K-Se batteries. Whereas the cathode enabled facile K ion diffusion and effective regulation of Se species, the incorporation of Co enhanced the reaction kinetics, thereby improving the overall performance of the K-Se batteries in terms of capacity output and lifetime. In a statement to Advances in Engineering, Professor Jingyu Sun, the corresponding author stated that their work provided a guideline for the innovative design of multifunctional Se host with potential for aiding the exploration of K-Se batteries.

Reference

Ding, Y., Cai, J., Sun, Y., Shi, Z., Yi, Y., Liu, B., & Sun, J. (2022). Bimetallic Selenide Decorated Nanoreactor Synergizing Confinement and Electrocatalysis of Se Species for 3D-Printed High-Loading K–Se Batteries. ACS Nano, 16(2), 3373-3382.

Advances in Engineering Advances in Engineering features breaking research judged by Advances in Engineering advisory team to be of key importance in the Engineering field. Papers are selected from over 10,000 published each week from most peer reviewed journals.

Advances in Engineering Advances in Engineering features breaking research judged by Advances in Engineering advisory team to be of key importance in the Engineering field. Papers are selected from over 10,000 published each week from most peer reviewed journals.