Significance Statement

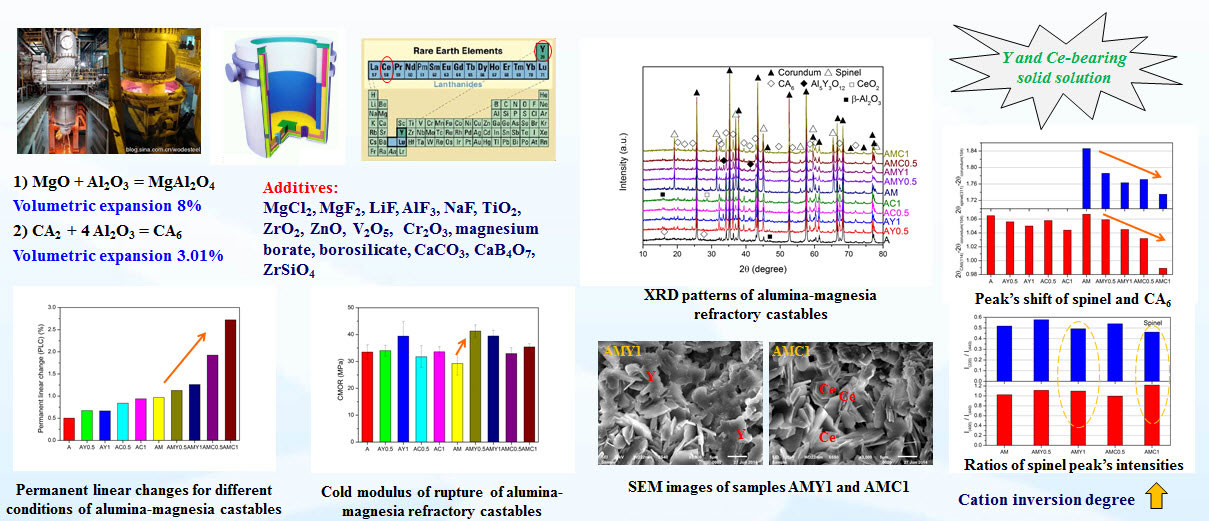

The development of novel techniques for metallurgy industries has coerced the production of better performance oriented castables. Recently, alumina-magnesia castables have been widely utilized in refractories since they possess better slag resistance than alumina-spinel castables. However, the in situ reactions of the calcium hexaluminate and spinel yield a significant amount of expansion which is critical in determining the properties of spinel forming alumina-magnesia castables.

Consequently, a solution for this problem has been found through the application of mineralizing compounds, which not only control the overall expansion but also have significant impact on phase and microstructure evolution of castables. Various additives have been used as mineralizers for accelerating the spinel formation reaction. Even so, application of oxides of rare earth elements as additives is quite popular due to its sintering behavior with alumina. Additives cutting across heavy and light rare earth elements are investigated here.

Researchers led by professor Wenjie Yuan from the State Key Laboratory of Refractories and Metallurgy at Wuhan University of Science and Technology in China investigated the effects of rare earth oxides addition on microstructure and properties of alumina-magnesia refractory castables. They hoped to compare with corundum castables as their reference, the mechanisms of rare earth oxides action in alumina-magnesia castables. Their research work is now published in the peer-reviewed journal, Ceramics International.

The research team begun by preparing both alumina-magnesia castables and corundum castables for use in evaluating yttria and ceria. After casting they molded the castables into types of specific dimensions. The castables were then cured at specific temperatures and humidity. Permanent linear change for calcined castables were recorded concurrently with the expansion curve of the bar samples during heating. The team then performed the cold modulus of rapture measurement for the castables. They then determined the phase compositions in the castables. Eventually, they observed the microstructure of the castables.

The authors of research observed that micro factors dominated the thermal expansion of the castables. The research team also observed that the effects of yttria on spinel solid solution castables was more prominent than calcium hexaluminate. A contrary observation was witnessed with respect to ceria. Moreover, the cation invasion degree of spinel was noted to increase with yttria and ceria addition. However, it was seen that excessive addition of yttria led to the formation of yttrium aluminum garnet. Ceria was observed to react adequately with other components in the matrix.

The study concluded that yttria and ceria have the potential to significantly increase the expansion of alumina-magnesia castables. Also, the cold modulus of rupture for alumina-magnesia castables with yttria and ceria has been noted to be more than those of the referenced calcined castables. Therefore, rare earth elements can be selected as alternative additives for design of alumina-magnesia refractory castables.

Reference

Wenjie Yuan, Qingyou Zhu, Chengji Deng, Hongxi Zhu. Effects of rare earth oxides additions on microstructure and properties of alumina-magnesia refractory castables. Ceramics International, volume 43 (2017) pages 6746–6750.

Go To Ceramics International Advances in Engineering Advances in Engineering features breaking research judged by Advances in Engineering advisory team to be of key importance in the Engineering field. Papers are selected from over 10,000 published each week from most peer reviewed journals.

Advances in Engineering Advances in Engineering features breaking research judged by Advances in Engineering advisory team to be of key importance in the Engineering field. Papers are selected from over 10,000 published each week from most peer reviewed journals.