Significance

The increasing global demand for space cooling and HVAC systems has raised concerns about their significant energy consumption and associated CO2 emissions. To address this issue, researchers at the University of Cambridge, led by Professor David Fairen-Jimenez, have made groundbreaking advancements in the development of energy-efficient adsorbent-based HVAC technologies. Their findings, published in the Journal Advanced Materials, introduce the concept of monolithic metal-organic frameworks (MOFs) as a solution to overcome the limitations of traditional sorbent materials and improve the performance of HVAC systems.

Traditional HVAC systems, including refrigeration and dehumidification processes, contribute to approximately 10% of global electricity use and generate approximately 1.13 gigatonnes of CO2 emissions annually. The demand for cooling systems is projected to triple by 2050, necessitating a paradigm shift towards energy-efficient technologies. Traditional adsorbent materials, such as silica gels and zeolites, have limitations in terms of tunability and regeneration energy requirements, making them unsuitable for sustainable HVAC systems.

MOFs offer remarkable improvements in water adsorption and regeneration energy requirements, making them promising candidates for HVAC applications. Unlike traditional sorbent materials, MOFs can be precisely designed at the molecular level, resulting in high porosity and optimal MOF-water interactions. With over 100,000 MOF structures compared to around 1,000 silica gels and zeolites, MOFs offer a diverse range of materials for various applications.

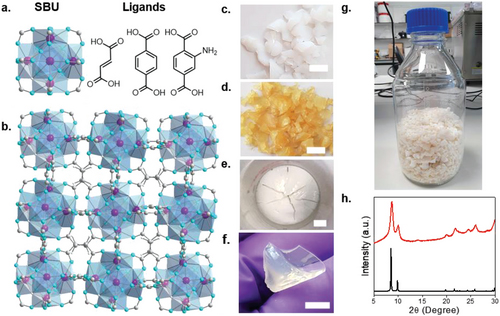

The deployment of MOFs in HVAC applications has been hindered by challenges related to MOF powder processing. Traditional shaping techniques result in a loss of surface area and porosity, reducing the performance of MOFs. However, the researchers have developed a sol-gel approach to synthesize three high-density, shaped, monolithic MOFs: UiO-66, UiO-66-NH2, and Zr-fumarate. These materials exhibit exceptional volumetric gas/vapor uptake, overcoming previous limitations in MOF-HVAC deployment.

To assess the performance of the monolithic MOFs, the researchers conducted extensive experiments and analyses. Small-angle X-ray scattering and lattice-gas models were used to visualize the monolithic structures and accurately predict their adsorption characteristics. The monolithic MOFs demonstrated high water adsorption capacities, facile desorption at low temperatures, and high coefficient of performance (COP) for chillers. The fragile MOF, Zr-fumarate, achieved a bulk density of 0.76 gcm−3 without compromising adsorption performance and exhibited a COP of 0.71 at a low regeneration temperature (≤ 100 °C).

The development of monolithic MOFs represents a significant advancement in the field of HVAC technologies. These shaped materials offer improved volumetric adsorption capacities compared to their powdered and pelletized counterparts. The research provides a viable route towards industrial production of MOFs in high-density, shaped bodies while maintaining their full adsorption performance. The findings have the potential to revolutionize the design and implementation of energy-efficient adsorbent-based HVAC systems.

The research conducted at the University of Cambridge has showcased the potential of monolithic metal-organic frameworks (MOFs) in revolutionizing energy-efficient HVAC systems. The development of high-density, shaped MOFs overcomes the limitations of traditional sorbent materials, enabling enhanced water adsorption capacities and low-temperature regeneration. These advancements pave the way for sustainable cooling solutions with reduced energy consumption and environmental impact. As further.

Reference

Çamur C, Babu R, Suárez Del Pino JA, Rampal N, Pérez-Carvajal J, Hügenell P, Ernst SJ, Silvestre-Albero J, Imaz I, Madden DG, Maspoch D, Fairen-Jimenez D. Monolithic Zirconium-Based Metal-Organic Frameworks for Energy-Efficient Water Adsorption Applications. Adv Mater. 2023 ;35(23):e2209104.

Advances in Engineering Advances in Engineering features breaking research judged by Advances in Engineering advisory team to be of key importance in the Engineering field. Papers are selected from over 10,000 published each week from most peer reviewed journals.

Advances in Engineering Advances in Engineering features breaking research judged by Advances in Engineering advisory team to be of key importance in the Engineering field. Papers are selected from over 10,000 published each week from most peer reviewed journals.