Significance

Technological advances in manufacturing field have led to the development of advanced laser cladding technology that generally integrates laser, numerical control, and computerized material processing. It has recently attracted significant attention of researchers attributed to the excellent thermal, mechanical and physical properties of the resulting substrate surfaces thus having potential applications in various fields such as aerospace and automobile industries.

Studies have shown that several research works have been conducted on various aspects of laser cladding since its invention with the aim of enhancing its efficiency. Unfortunately, the majority of the existing studies have ignored the effects of temperature variation on the physical and mechanical properties of the resulting substrates as well as the powder particles. To this end, researches have been looking for alternatives and have identified the use of computers to study different laser cladding mechanisms based on finite element methods.

Recently, University of Science and Technology Liaoning researchers: Dr. Chang Li, Mr. Zhibin Yu (MSc candidate), Mr. Jiangxiang Gao (MSc candidate), Jinyue Zhao (MSc candidate) and Professor Xing Han from the School of Mechanical Engineering and Automation developed a three-dimensional mathematical model based on the thermo-elastic-plastic-flow in laser cladding process. Specifically, they added Fe60 powder on an ASTM 1045 substrate. Furthermore, Calculation of phase diagram technique was utilized to solve the model by determining the temperature variation curves of the powder particles and substrate physical properties. Their research work is currently published in the research journal, Surface and Coatings Technology.

Briefly, research team cross-examined the interaction between the laser energy beam and the powder flow. They also examined the influence of buoyancy and surface tension on the flow of the fluid during melting. Next, the evolution and distribution of the temperature and velocity fields during laser cladding were also investigated. The authors further used solidification growth rate and temperature gradient techniques to determine the morphology and solidification structure of the melt pool through. To actualize their study, they compared the experimental results with the calculated results.

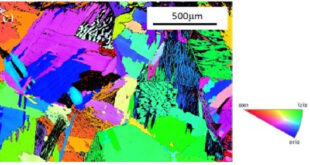

The authors observed that the accuracy of the developed model was significantly improved. Moreover, there was a commended agreement between the experimental and calculated results. Consequently, it was noted that significant temperature change was exhibited in front of the melt pool. Furthermore, planar crystals, thick dendrites, and equiaxed crystals were displayed at the bottom, medium and top of the laser cladding layer.

In summary, the Dr. Chang Li led team successfully investigated both numerically and experimentally the cladding process using the same materials and process parameters. The feasibility of the developed model was also validated by taking into consideration the similarity between the simulation and experimental results. Therefore, the study will lead to more efficient and advanced laser cladding technology that will further advance various aspects of manufacturing processes.

Reference

Li, C., Yu, Z., Gao, J., Zhao, J., & Han, X. (2019). Numerical simulation and experimental study of cladding Fe60 on an ASTM 1045 substrate by laser cladding. Surface and Coatings Technology, 357, 965-977.

Go To Surface and Coatings Technology Advances in Engineering Advances in Engineering features breaking research judged by Advances in Engineering advisory team to be of key importance in the Engineering field. Papers are selected from over 10,000 published each week from most peer reviewed journals.

Advances in Engineering Advances in Engineering features breaking research judged by Advances in Engineering advisory team to be of key importance in the Engineering field. Papers are selected from over 10,000 published each week from most peer reviewed journals.