Significance

Graphene, a monolayer of carbon atoms bounded within hexagonal lattice, has attracted significant research attention since its discovery. Graphene exhibits remarkable mechanical, thermal, and electrical properties desirable for different applications such as electronic devices. Unfortunately, their application is limited by its zero-energy band gap. Based on the literature, this drawback can be overcome by either modifying the graphene through doping, introducing defects etc., or by using graphene nanoribbons. Specifically, graphene nanoribbons, narrow strips of graphene, possess unique properties and can open up the band gap without affecting electron mobility, and have been identified as potential candidates for various applications.

The distinct superiority of graphene nanoribbons over graphene has attracted research attention leading to the development of several methods for synthesizing graphene nanoribbons. Considering that the properties and applications of graphene nanoribbons are largely dependent on their shape and size, high precision design and construction of graphene nanoribbons at the atomic scale is of critical importance in ensuring graphene nanoribbons with desirable geometry and properties. Nevertheless, this has remained a great challenge and cannot be obtained by the available synthesis methods. Previously, research revealed that small materials with precise microscale sizes could be created by cutting a large piece. Consequently, hydrogen functionalized graphene, otherwise known as pseudo cracks, can potentially produce precise GNRs even though the approach has not been verified experimentally.

Motivated by these results, a team of researchers: Changguang Qi, Dr. Wenfei Peng, Prof. Lijun Yi, Ji Wang from Ningbo University in collaboration with Prof. Jianxin Zhou from Nanjing University of Aeronautics and Astronautics, and Prof. Yingyan Zhang from RMIT University explored the feasibility of using hydrogen pseudo-cracking method to synthesize atomically precise graphene nanoribbons from graphene. The main objective was to obtain precise graphene nanoribbons with desirable width, edge type and properties. Their work is currently published in the research journal, Nanotechnology.

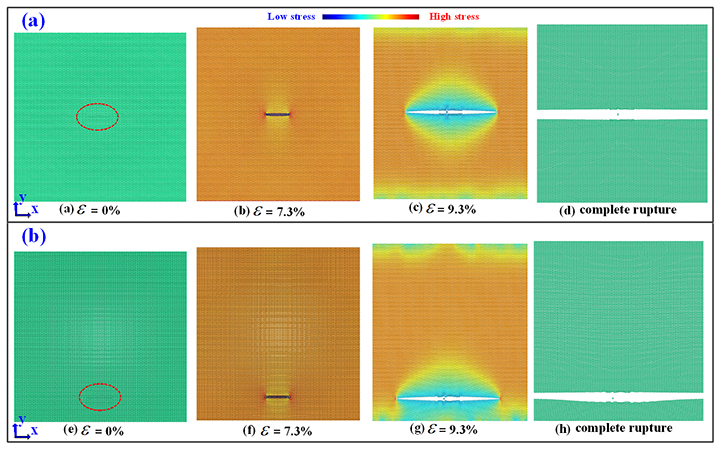

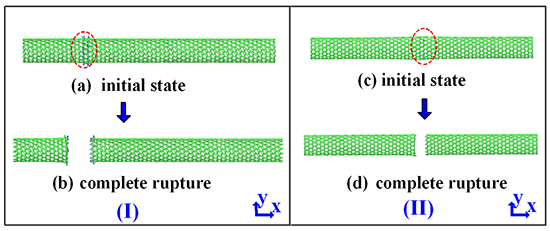

In their approach, the authors investigated how hydrogenated graphene can be precise cut into the desired shape, size, and edge using molecular dynamics simulations. The resulting hydrogenated pseudo cracks were modulated by different hydrogen patterns and then applied to control the fracture path. Also, the effects of the programmable hydrogen pseudo cracks on the production of graphene nanoribbons were investigated. Graphene nanoribbons with different desirable width can be obtained in atomically precise by setting the hydrogen pseudo crack position (Fig 1).

Results showed that the hydrogenated pseudo cracks triggered graphene fracturing along the hydrogenation line, allowing the precise cutting of graphene into the desired graphene nanoribbons. By manipulating the position as well as the dimensions of the hydrogenated pseudo-cracks, precise graphene nanoribbons with appropriate width, edge type, and desired properties were synthesized. Notably, hydrogenation pseudo-cracks exhibited significant influence on the cutting of graphene into graphene nanoribbons. Longer hydrogen pseudo-cracks were more efficient for controlling fracture paths at any crack width, while wider pseudo-cracks did not only increase the fracture stress but also resulted in the problems of crack bifurcation and multiple cracks. On that note, long and narrow hydrogen pseudo-cracks patterned along the armchair direction emerged suitable for accurate cutting and production of smooth-edged graphene nanoribbons.

In summary, the study reported a new cutting method for the precise production of graphene nanoribbons from graphene. The approach involved atomically precise cutting using hydrogenation modification of graphene as pseudo cracks. Molecular dynamics simulation results demonstrated the precise cutting of hydrogenated graphene into graphene nanoribbons with desirable size, edge, and properties through effective control of the fracturing path. Moreover, long and narrow hydrogen pseudo-cracks patterned in the armchair direction were highly recommended for smooth-edged. In a statement to Advances in Engineering, Prof. Lijun Yi and Yingyan Zhang noted that the hydrogenation-assisted cutting method offered feasible means of precise cutting of graphene into desirable graphene nanoribbons and would pave the way for the well-defined and high-performance graphene nanoribbons for numerous applications. They stressed that this a promising approach can be widely extended to other application, which should be also valid for cutting other 2D Materials into nanoribbons effectively and accurately, even for cutting carbon nanotube with desired length (Fig 2).

Reference

Qi, C., Peng, W., Zhou, J., Yi, L., Wang, J., & Zhang, Y. (2020). From graphene to graphene ribbons: atomically precise cutting via hydrogenation pseudo-crack. Nanotechnology, 31(41), 415705.

Advances in Engineering Advances in Engineering features breaking research judged by Advances in Engineering advisory team to be of key importance in the Engineering field. Papers are selected from over 10,000 published each week from most peer reviewed journals.

Advances in Engineering Advances in Engineering features breaking research judged by Advances in Engineering advisory team to be of key importance in the Engineering field. Papers are selected from over 10,000 published each week from most peer reviewed journals.