Significance Statement

Inkjet printing technique has been extensively used for the deposition of functional materials. It can also serve as an etching technique to fabricate surface patterns by printing etching inks onto soluble polymer substrates. However, inherent transverse ink diffusion leads to low feature resolution for the inkjet etching technique.

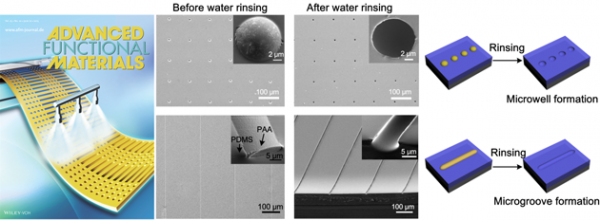

Scientists from the Key Laboratory of Green Printing at Institute of Chemistry, Chinese Academy of Sciences developed an inkjet imprinting technique to fabricate microstructures with high resolution by combing the inkjet printing technique with imprinting lithography. By using ink droplets as templates, they facilely fabricated concave microstructures, such as microwells and microgrooves on polydimethylsiloxane (PDMS) surfaces in a highly controllable manner. This low-cost microfabricating strategy could be anticipated to find numerous applications in the large-scale fabrication of microfluidic chips, biochips and various functional devices.

Journal Reference

Advanced Functional Materials, Volume 25, Issue 22, pages 3286–3294, 2015.

Bin Bao1,2, Jieke Jiang1,2, Fengyu Li1,Pengchao Zhang1,2, Shuoran Chen1,2,Qiang Yang1,2, Shutao Wang1, Bin Su1,Lei Jiang1 , Yanlin Song1,*

[expand title=”Show Affiliations”]- Beijing National Laboratory for Molecular Sciences (BNLMS), Key Laboratory of Green Printing, Key Laboratory of Organic Solids, Institute of Chemistry, Chinese Academy of Sciences, Beijing, P. R. China

- School of Chemistry and Chemical Engineering, University of Chinese Academy of Sciences, Beijing, P. R. China

Abstract

Concave microstructures such as microwells and microgrooves are widely utilized in fields such as biochips, microfluidics, and functional devices. Previously, concave microstructure fabrication was mostly based on laser etching or lithography which is either costly or of multisteps. The inkjet etching method is a direct structuring technique, but limited by its inherent transverse ink diffusion that leads to low feature resolution. Nanoimprint lithography can reach submicro and even nano ranges, whereas an elaborate template is needed. Thus, it is still a challenge to realize controllable fabrication of concave microstructures in large areas with high efficiency and resolution. Here, a template-free strategy to fabricate concave microstructures with high resolution by inkjet imprinting is provided. In this method, a sacrificial ink is inkjet-printed onto a precured viscoelastic surface and imprints its shapes to construct concave microstructures. The morphology of the microstructures could be adjusted by controlling the interaction between the two immiscible phases. The microwells/microgrooves could be used to pattern single cells and functional materials such as optical, electronic, and magnetic nanoparticles. These results will open a new pathway to fabricate concave microstructures and broaden their applications in various functional devices.

© 2015 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim

Go To Advanced Functional MaterialsFigure Legend: Sacrificial polyacrylic acid (PAA) solution ink is inkjet-printed onto pre-cured PDMS surfaces. Microdots or microwires are constructed depending on the printed ink drop distances. The microdots and microwires imprint their shapes onto the pre-cured PDMS surfaces, and these shapes can be kept by completely solidifying the underlying surfaces. Finally, microwells and microgrooves are constructed on the surfaces by rinsing away the sacrificial PAA ink.

Advances in Engineering Advances in Engineering features breaking research judged by Advances in Engineering advisory team to be of key importance in the Engineering field. Papers are selected from over 10,000 published each week from most peer reviewed journals.

Advances in Engineering Advances in Engineering features breaking research judged by Advances in Engineering advisory team to be of key importance in the Engineering field. Papers are selected from over 10,000 published each week from most peer reviewed journals.