Significance

Recent advancement in technology has led to the development of high-performance composite materials with remarkable properties for desired applications. More than often, composites materials require additional reinforcement to enhance their properties and functionalities. However, these materials are susceptible to failures due to several causes like fatigue and mechanical damage. As such, researchers have been looking for alternative methods for improving the mechanical properties of composite materials and have identified establishing the relationship between the mechanical and structural properties as a promising solution. In particular, three-dimensional needle-punched carbon fiber composites have attracted significant attention of researchers owing to their relatively low cost and good structural mechanical properties as compared to their conventional counterparts. This has made them viable candidates for use as reinforcing agents in carbon fiber-silicon carbide ceramic composites.

Presently, several approaches have been developed to investigate the structural-mechanical relationship in composites. Unfortunately, little has been reported about the inter-relationship between the microstructure components and the mechanical response of the materials. In a recently published literature, X-ray computed tomography has been used to observe, characterize and analyze the information gathered from the structure within the materials. Even though this method can be used to quantify different materials under various environmental conditions, there is a great need to improve their efficiency.

To this note, a group of researchers: Fan Wan, Rongjun Liu, Dr. Yanfei Wang, Yingbin Cao, and Dr. Changrui Zhang at the National University of Defense Technology together with Professor James Marrow at the University of Oxford investigated the damage development in three-dimensional braided carbon-fiber composites. In particular, they utilized the digital volume correlation of X-ray computed tomography of images to characterize the development of internal cracks due to compressive loading. Their research work is currently published in the journal, Composite Structures.

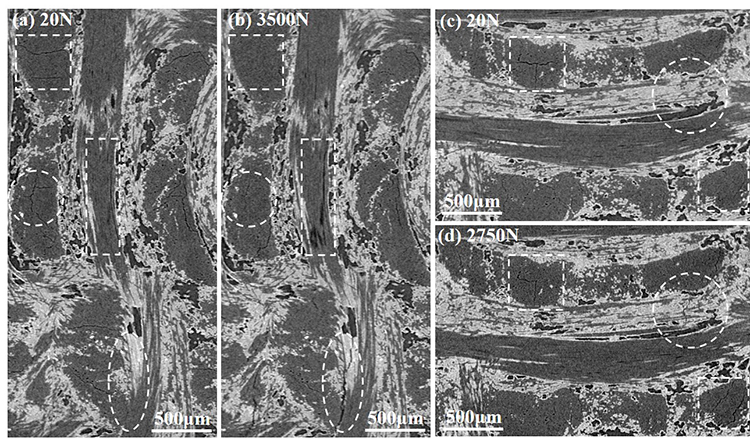

In brief, the authors initiated the research work by preparing a three-dimensional needle-punched carbon-silicon carbide ceramic composite. Secondly, they observed the evolution of the mechanical damage under compressive loading as well as its response to increased loading. The compressive load was applied to the material structure in three different ways: obliquely, longitudinally and transversely. Fundamentally, they intended to clarify the significance of the needle-punched fiber reinforcement in enhancing the material integrity in terms of properties, durability and performance.

The authors observed the existence of cracks within the microstructure before application of the compressive loads. This was attributed to the induced thermal strains. On the other hand, the direction of the loading as well as the material’s microstructure significantly influenced the growth and propagation of the cracks.

In summary, the research team successfully analyzed the underlying mechanisms leading to the compression failure of three-dimensional needle punched carbon-silicon carbide ceramic composites. In general, the difference in thermal expansion between the material’s constituents results in intrinsic defects that affect the microstructure and further leads to compression failures. Altogether, the study provides essential information that will advance the development of high-performance carbon-silicon carbide ceramic composites.

Reference

Wan, F., Liu, R., Wang, Y., Cao, Y., Zhang, C., & Marrow, T. (2019). In situ observation of compression damage in a 3D needled-punched carbon fiber-silicon carbide ceramic matrix composite. Composite Structures, 210, 189-201.

Go To Composite Structures Advances in Engineering Advances in Engineering features breaking research judged by Advances in Engineering advisory team to be of key importance in the Engineering field. Papers are selected from over 10,000 published each week from most peer reviewed journals.

Advances in Engineering Advances in Engineering features breaking research judged by Advances in Engineering advisory team to be of key importance in the Engineering field. Papers are selected from over 10,000 published each week from most peer reviewed journals.