Significance Statement

Hydrophobic coatings find wide applications in anti-wetting, lowering friction resistance by reducing solid-liquid interaction and anti-rusting. Super-hydrophobic surfaces with more than 150° water contact angles are desirable for anti-corona activities, anti-snow adherence and antibacterial effects owing to their superior water-shedding functionality. Super-hydrophobic surfaces can be obtained through surface roughness with reduced surface energy. However, these unique properties originate from limited area of contact between water and solid and the developed air-layer at the interface.

The lifespan of the developed air layer between water and the solid is often inadequate. The layer is easily eliminated by friction with water or collision with a droplet. Soon after the air layer is removed, a drop in the performance of the water-shedding is deteriorated due to its original surface roughness. Above all, surface roughness leads to surface staining making outdoor durability hard to achieve. Therefore, synthesizing a solid-liquid bulk composite in which the liquid droplet does not come into contact with the solid would be helpful.

In a recent paper published in Journal of Materials Science researchers led by professor Akira Nakajima at Tokyo Institute of Technology in Japan, prepared in their study, a solid-liquid bulk composite using a silicone oil, porous glass, and fluoroalkylsilane. The team investigated the effect of droplet viscosity on the sliding of the droplet on the solid-liquid bulk composite with varying droplet viscosity while maintaining its surface energy with a water-glycerin solution.

The authors precleaned a porous glass and then coated fluoroalkylsilane on its surface. They then impregnated silicone oil into the silane-coated glass and used a sessile drop method to determine the contact angles. They used water-ethanol and water glycerin blends, and water as droplet liquids for their study. Water-ethanol blend was employed for surface energy computation while the water-glycerin one was applied for the evaluating the impact of liquid viscosity.

The team analyzed the contact angles of the silane coating using a water-ethanol blend by altering the liquid mixing ratios (surface energy) and found that the surface energy for the fluoroalkylsilane coatings was approximately 16.0 mN/m.

The practical values of the spreading coefficients computed for the developed solid-liquid bulk composite through the pendant drop method indicated that the solid surface was not in direct contact with the water and the impregnated oil was spread between water and solid surfaces. Impregnating oil reduced contact and sliding angles. The drop in the contact angle was pegged at the phase change from air to oil in the porous glass. Decrease in the sliding angle resulted from the drop of probability for contacting the pining portion for the three-phase contact line motion on the oil surface.

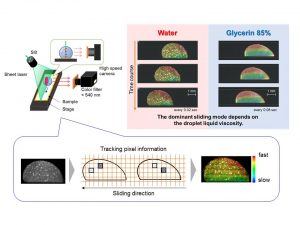

From the results, the authors concluded that water droplets slid down majorly by slipping mode. The effect of rolling was found to increase steadily with droplet viscosity. When the concentration of glycerin was raised to more than 65%, rolling velocity was equal to the total velocity. The researchers found that for the water glycerin mixture, the flow around the droplet perimeter was faster than around the bottom side. This indicated that the liquid viscosity affected the droplet sliding.

The researchers managed to prepare a solid-liquid bulk composite without a contact between the hydrophobic surface and the liquid droplets. The sliding mode moved from slipping to rolling with increasing viscosity. Viscous energy dissipation computation suggested that the dominant elements were affected by the droplet viscosity.

References

Kota Yokoyama1, Munetoshi Sakai2, Toshihiro Isobe1, Sachiko Matsushita1, and Akira Nakajima1. Droplet viscosity effects on dynamic hydrophobicity of a solid–liquid bulk composite prepared from porous glass. J Material Science, volume 52 (2017), pages 595–604.

[expand title=”Show Affiliations”]- Department of Materials Science and Engineering, School of Materials and Chemical Technology, Tokyo Institute of Technology, Tokyo, Japan

- Strategic Coordination of Research and Intellectual Properties, Meiji University, Kawasaki, Japan

Advances in Engineering Advances in Engineering features breaking research judged by Advances in Engineering advisory team to be of key importance in the Engineering field. Papers are selected from over 10,000 published each week from most peer reviewed journals.

Advances in Engineering Advances in Engineering features breaking research judged by Advances in Engineering advisory team to be of key importance in the Engineering field. Papers are selected from over 10,000 published each week from most peer reviewed journals.