Significance

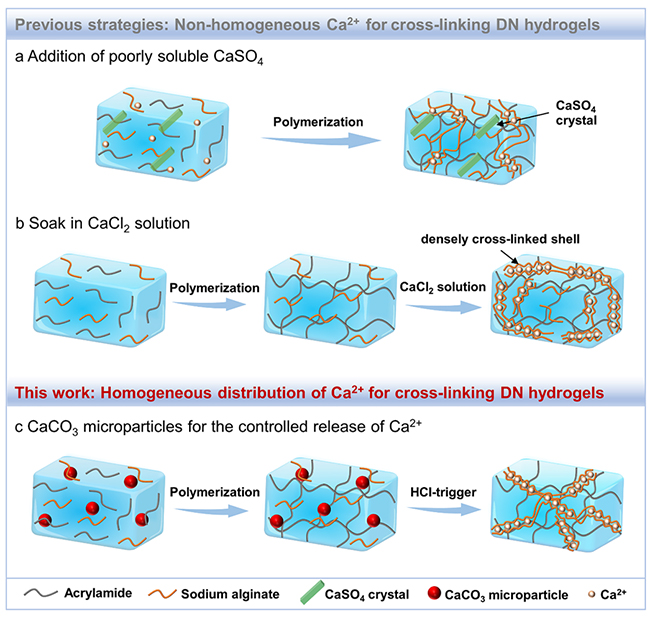

Hydrogels are three-dimensional networks of hydrophilic polymers that can absorb and retain large amounts of water. Hydrogels have attracted considerable attention for various applications in materials science and biomedical engineering, such as tissue scaffolds, actuators, drug delivery systems, and wearable devices. However, conventional hydrogels often suffer from low mechanical strength and toughness, which limit their practical use. To overcome this limitation, double-network hydrogels have been developed, which are a class of hydrogels with a unique structure consisting of two networks: a primary network that provides mechanical strength and a secondary network that imparts toughness to the hydrogel. The primary network is typically composed of a rigid, cross-linked polymer network, such as polyacrylamide, while the secondary network is composed of a flexible, linear polymer, such as sodium alginate, that is physically interpenetrated within the primary network. The utility of double-network hydrogels lies in their unique combination of mechanical properties, which make them well-suited for a variety of applications. The primary network provides stiffness and mechanical strength, while the secondary network provides toughness and resistance to fracture. As a result, double-network hydrogels can be stretched to high strains without breaking and can absorb large amounts of energy without undergoing catastrophic failure. Double-network hydrogels have been used in a variety of applications, including tissue engineering, drug delivery, and soft robotics. In tissue engineering, double-network hydrogels have been used as scaffolds to support the growth of cells and tissues due to their mechanical properties and biocompatibility. In drug delivery, double-network hydrogels have been used to encapsulate and release drugs in a controlled manner. In soft robotics, double-network hydrogels have been used to create soft, flexible robots that can adapt to changing environments. The double-network hydrogels composed of biocompatible sodium alginate (SA)/polyacrylamide (PAM) are a promising class, which are typically cross-linked with calcium ions (Ca2+). However, the use of calcium salts as cross-linkers typically induces structural inhomogeneity and reduces the mechanical properties of the resultant hydrogels. Therefore, there is a need for a novel strategy to fabricate homogeneous and high-performance SA/PAM double-network hydrogels for flexible devices.

In a new study published in the peer-reviewed Journal of Materials Chemistry A, by Ms Xiaohui Zhang, Dr. Huimin Geng, Ms Xunhui Zhang, Prof. Yaqing Liu, Prof. Jingcheng Hao and Prof. Jiwei Cui from Shandong University, it demonstrated that by pre-seeding calcium carbonate (CaCO3) microparticles into SA/PAM double-network hydrogels, and subsequently inducing the release of calcium ions from the microparticles in an acidic solution, it is possible to improve the mechanical characteristics and strain sensitivity of the hydrogels for use in the development of highly sensitive wearable sensors. Engineering of ultrasensitive wearable sensors involves the design, development, and integration of advanced materials, electronics, and signal processing techniques to create wearable devices that can detect and measure physiological or environmental signals with high sensitivity and accuracy. Ultrasensitive wearable sensors have a wide range of potential applications, including monitoring of health and wellness, early detection of disease, and environmental monitoring. They can provide continuous, non-invasive monitoring of physiological and environmental signals, enabling early detection of changes and interventions before they become more serious.

The key innovation in Professor Jiwei Cui’s study is that the researchers pre-seeded CaCO3 microparticles into the hydrogel, which could release calcium ions when exposed to acidic solution. The calcium ions subsequently cross-linked the SA chains to form sacrificial ionic bonds that enhanced the mechanical strength and toughness of the hydrogel. The mechanical properties of the hydrogel could also be tuned by changing the amount of CaCO3 microparticles and the trigger time of the acid solution. The hydrogel showed excellent self-healing and fatigue resistance due to the reversible nature of the ionic bonds. Moreover, the hydrogel had high electrical conductivity due to the presence of mobile ions in the network, which enabled it to function as a strain sensor. The hydrogel strain sensor had high sensitivity, wide detection range, fast response time, and good durability under various environmental conditions. The sensor could monitor human motions such as finger bending, wrist rotation, facial expression, and speech recognition with high accuracy and reliability. The sensor could also be integrated with other electronic components to form flexible circuits that could be attached to various substrates such as paper, cloth, or skin. Furthermore, the sensor could be applied to monitor the pain signal induced by an in-situ cascade reaction at a wound site in a diabetic rat model. The pain signal was detected by measuring the change in resistance of the sensor before and after injecting glucose oxidase and azithromycin into the wound, which triggered a chemical reaction that produced reactive oxygen species that caused inflammation and pain in the wound tissue. The inflammation and pain induced a contraction of the wound tissue, which increased the strain and resistance of the sensor, indicating a pain signal that could be quantified by measuring the resistance change. The authors indeed provided a controllable strategy to engineer stretchable and tough double-network hydrogels for potential applications in flexible devices.

In summary, Professor Jiwei Cui and co-workers developed a new type of hydrogel that can be tuned by pre-seeding CaCO3 microparticles and acid-triggered cross-linking to achieve high mechanical and electrical properties. The hydrogel can be used as a strain sensor for wearable devices that can monitor human motions and pain signals.

Reference

Zhang X, Geng H, Zhang X, Liu Y, Hao J, Cui J. Modulation of Double-Network Hydrogels via Seeding Calcium Carbonate Microparticles for the Engineering of Ultrasensitive Wearable Sensors. Journal of Materials Chemistry A. 2023, 11, 2996.

Advances in Engineering Advances in Engineering features breaking research judged by Advances in Engineering advisory team to be of key importance in the Engineering field. Papers are selected from over 10,000 published each week from most peer reviewed journals.

Advances in Engineering Advances in Engineering features breaking research judged by Advances in Engineering advisory team to be of key importance in the Engineering field. Papers are selected from over 10,000 published each week from most peer reviewed journals.