Significance

Geopolymers are inorganic, ceramic-like, materials that form long-range, covalently bonded, non-crystalline (amorphous) networks. These materials are synthesized from reactive aluminosilicate precursors and alkali solutions. As such, they have a slew of applications under their name: for instance, commercially produced geopolymers may be used for fire- and heat-resistant coatings and adhesives, medicinal applications, high-temperature ceramics, new binders for fire-resistant fiber composites, toxic and radioactive waste encapsulation and new cements for concrete – among other uses. Intrinsically, geopolymers are mesoporous, however, they have highly dense structures exhibiting low permeability. Consequently, introduction of higher and interconnected porosity in geopolymers could advance their utility particularly in adsorption, filtration and separation applications. To this end, several reports have been published in line with this quest where various techniques to generate additional porosity in geopolymers have been established. Unfortunately, there are no reports on geopolymers with interconnected macroporosity.

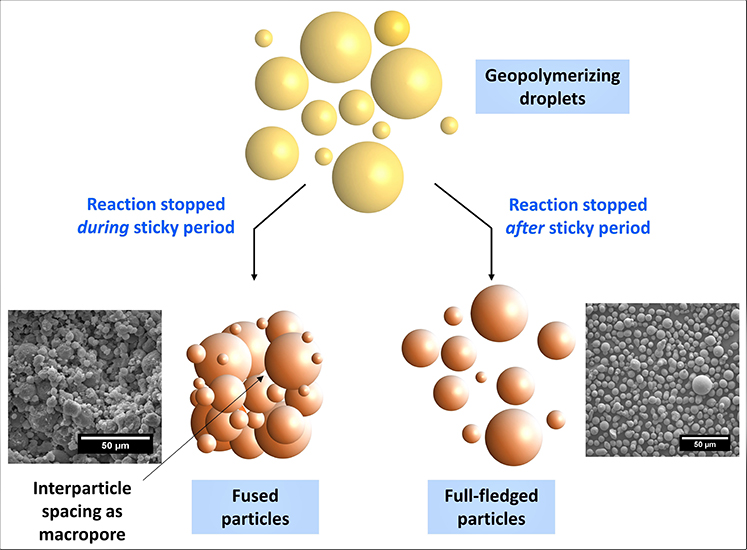

To address this, a team of researchers form the Department of Chemistry and Biochemistry at University of Texas: Nimisha Thakur (PhD candidate), Dr. Choyce Weatherly, Dr. Rasangi Wimalasinghe and led by Professor Daniel Armstrong developed a novel approach to fabricate geopolymer monoliths with interconnected macroporosity and a permeable structure. Their objective was to boost the permeability of the geopolymer monoliths using an alternative approach, other than the previously reported techniques, namely: use of blowing agents, in situ saponification and use of surfactants. They synthesized geopolymer monoliths by exploiting the so-called “sticky period” which occurs during inverse suspension polymerization. In their approach, the aqueous geopolymer slurry, consisting of potassium hydroxide, fumed silica and natural metakaolin, was dispersed in a continuous phase of soybean oil. The droplets were brought together during the sticky period in which the essentially individual droplets can coalesce but not re-divide because of the partially polymerized matrix.

The authors reported that the sticky period depended on the synthetic conditions of the reaction, particularly on the stirring speed and temperature. Remarkably, the team observed that by fusing particles taken during the sticky period, a solid structure with inter-particle spacing as macroporosity could be produced. Their work is currently published in the Journal of the American Ceramic Society.

In summary, Professor Daniel Armstrong and his research team demonstrated the facile fabrication of interconnected macroporosity and permeability in geopolymer monoliths using their novel approach termed: “sticky period particle fusion”. The study established that the sticky period can be used to induce permeability in the geopolymer monolith. Furthermore, the conditions were also reported to affect the pore properties like surface area and pore volume hence the structure and the physical properties can be manipulated using different conditions- thus creating a stepping stone for further studies. In fact, in a statement to Advances in Engineering, Professor Daniel Armstrong pointed out that the optimization of the reaction conditions and geopolymer composition to get the specific structural features like high permeability, high surface area, and uniform pore structure was still under investigation in their laboratory. Overall, this simple and unique approach can be applied for synthesis of other materials. “Sometimes new, enhanced utility materials can be made by altering the properties and synthesis of older, well-known materials” said Professor Daniel Armstrong to Advances in Engineering.

Reference

N. Thakur, C. Weatherly, R. Wimalasinghe, D. Armstrong. Fabrication of interconnected macroporosity in geopolymers via inverse suspension polymerization. Journal of American Ceramics Society 2019; volume 102: page 4405–4409.

Advances in Engineering Advances in Engineering features breaking research judged by Advances in Engineering advisory team to be of key importance in the Engineering field. Papers are selected from over 10,000 published each week from most peer reviewed journals.

Advances in Engineering Advances in Engineering features breaking research judged by Advances in Engineering advisory team to be of key importance in the Engineering field. Papers are selected from over 10,000 published each week from most peer reviewed journals.