M. Giglio, A. Manes , F. Viganò

International Journal of Mechanical Sciences, Volume 54, Issue 1, January 2012

Abstract

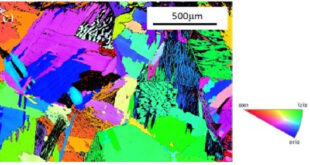

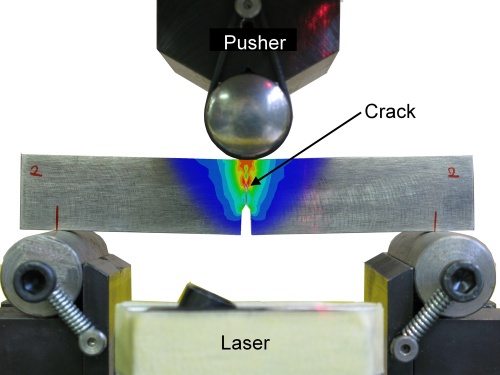

The simulation of ductile fracture in real components is becoming a strategic issue in numerical simulations. Numerical simulations of crashes, forming processes, impacts and fractures are reliable only if carried out with an accurate material calibration. The topics involved in this kind of simulation require a complete calibration of both the true stress–strain curve and the failure. The focus of this work is the accurate calibration of the constitutive relations of the titanium alloy Ti–6Al–4V. The approach proposed is based on different experimental tests supported by numerical simulations performed by means of detailed FE models. The Bao–Wierzbicki ductile failure criterion is calibrated using a total of 11 specimens. These specimens are tested on a multiaxial test machine to investigate the failure at different stress triaxialities. Furthermore, the sensitivity to the mesh size and the assessment of the calibration accuracy are analysed in detail on different components in order to verify the geometry transferability.

Website: SIGMA LAB – PoliMi

Go to Journal

Advances in Engineering Advances in Engineering features breaking research judged by Advances in Engineering advisory team to be of key importance in the Engineering field. Papers are selected from over 10,000 published each week from most peer reviewed journals.

Advances in Engineering Advances in Engineering features breaking research judged by Advances in Engineering advisory team to be of key importance in the Engineering field. Papers are selected from over 10,000 published each week from most peer reviewed journals.